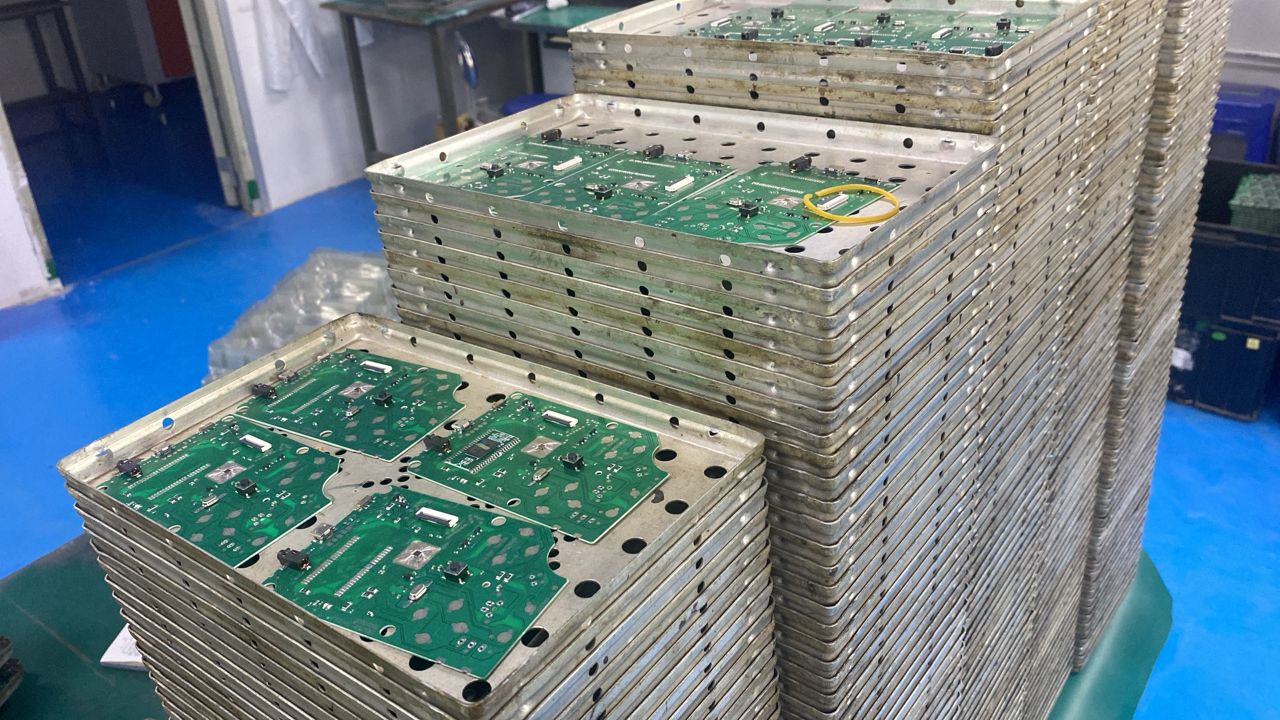

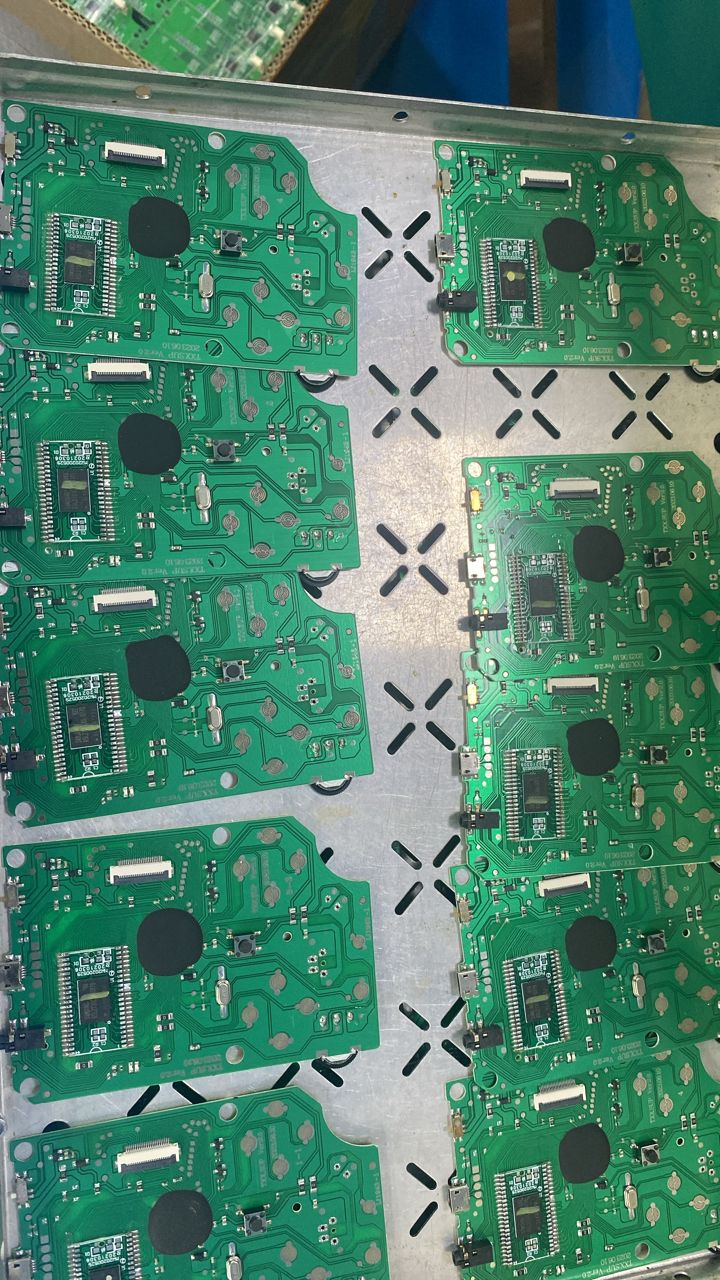

We specialize in delivering top-tier PCBA's featuring diverse capabilities and comprehensive testing functionalities, ensuring impeccable quality across the board.

Design, Create, Innovate. "Precision Additive Manufacturing: Elevating Product Creation with 3D Printing"

We provide plastic and metallic enclosures in different fields of electronic, electrical, communication, medical, industrial and research projects purposes.

We specialize in delivering top-notch firmware, software, and mobile app development solutions tailored specifically for IoT products. With a keen focus on innovation and cutting-edge technology, we empower businesses to harness the full potential of their IoT devices.